Subgrade Attrition

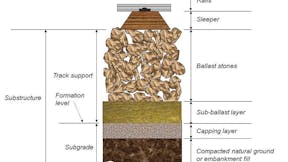

Mud pumping can also occur from subgrade attrition. Attrition can occur when the subgrade consists of a soft rock or a hard clay layer that is in direct contact with the ballast and water is present above the contact between the two materials. During loading, the ballast is pushed into the hard layer causing local subgrade failure. Mud slurry is produced from failure of the fine-grained subgrade. The mud migrates upward during subsequent loading cycles fouling the ballast and eventually pumping at the ground surface.

Stabilization

Fouled ballast problems can be treated by removing the degraded ballast and replacing it with a more durable material. Placing a protective blanket of subballast, or even better: a resilient mat layer, between the hard subgrade layer and the ballast can often control subgrade attrition.

Several methods are in use for treating progressive shear failure and ballast pocket problems. These methods include, but are not limited to, increasing the ballast thickness, placing an asphalt layer between the ballast and subgrade, and installing geosynthetics or resilient confinement layers over the subgrade. Another method involves pressure injection of various mixes (e.g. lime or cement based) to fill ballast pocket voids and/or chemically stabilize the subgrade soils.

Each of the above methods may be appropriate under certain circumstances; however, each has its limitations. Undercutting to remove fouled ballast is expensive, costing up to 30.000 EUR/km for a single track.

Increasing the ballast thickness to treat progressive shear and plastic deformation problems may be severely limited by clearance constraints. A possible remedy is the use of resilient subballast mats as previously mentioned. In addition, the ballast pockets should still be drained or the use of resilient mats alone may not solve the problem.

Installing asphalt layers or geosynthetic products requires removal of the entire track structure. Slurry injection methods can be used without removing the track; however, their effectiveness is highly susceptible to mix design, subgrade soil properties, injection patterns and methods. Furthermore, proper implementation of these methods requires a thorough understanding of the subsurface conditions. Subsurface explorations and laboratory testing should be performed and proper design procedures used when available.

Slope stabilization methods commonly used by the railroads include removal and replacement of the slide mass, toe buttresses, various retaining wall schemes, pile driving, excavation to unload the head of the slide, and subsurface drainage techniques. The appropriate stabilization method will depend on site constraints and subsurface conditions. In many cases, several methods may be appropriate for a particular site and the method selected is based solely on cost.